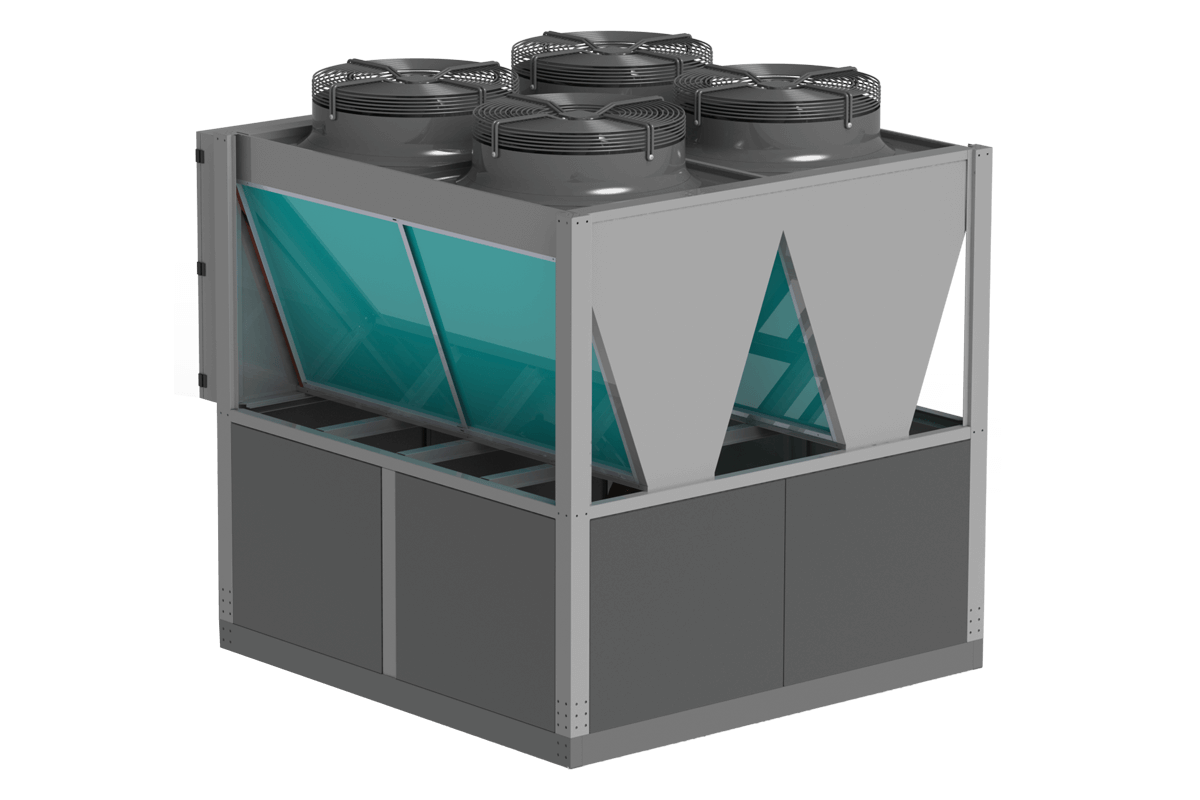

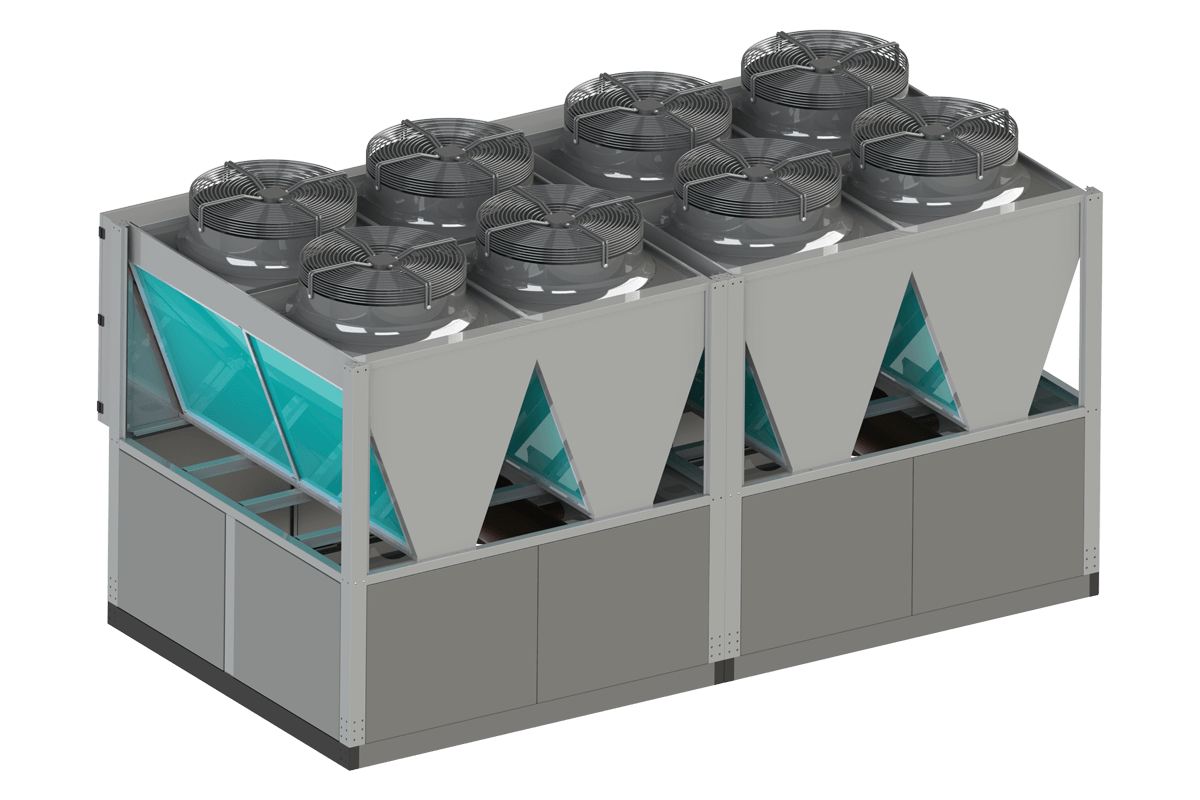

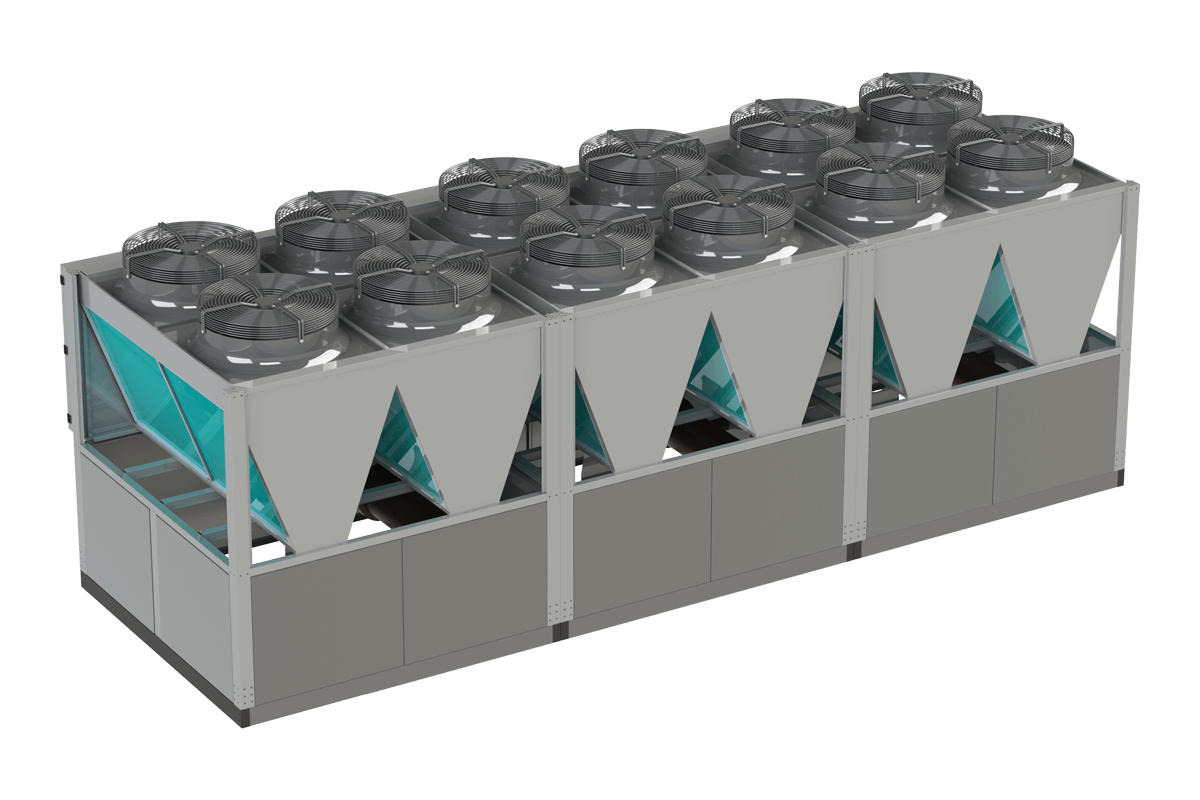

Description

Body

Easy To Remove Coil And Fan

Forming For High Body Strength

Drain Tray For Water Drainage From Condenser

Separation Of Evaporator And Piping From Condenser Section

Body Coating

After Production And Initial Washing And A Primer Coat, The Device Is Painted With Electrostatic Powder Paint.

Chassis

It Is Made Of Welded Standard Gutters Of Appropriate Size For The Capacity Of The Machine.

Compressor

Using Low-Noise Danfoss Or Copeland Scroll Compressors And The Ability To Dual-Circuit Capacities

Condenser

Condenser Design Up To 40 Degrees Outside Temperature

Possibility Of Adding Fans In Stages Due To The Airtightness Of The Coils

Possibility Of Producing Condenser Coils With Coating (Blue Fin)

Fin Density Up To 12 Fins Per Inch For Minimal Pressure Drop

Condenser Fan

Zillabag Low Speed Axial Condenser Fans

Evaporator

Shell-Tube Evaporator For Long Life And Frost Prevention In Cold Season

6mm Thick Evaporator Shell And Use Of 0.8mm Thick Copper Tube

Evaporator Nut Connections And No Welding In The Shell Tube

Antifreeze Built Into The Evaporator And Thermostat To Regulate Water Temperature

Water Pipe Strainer To Filter Circuit Water And Prevent Sand From Entering The Evaporator

Using A Flow Switch To Control The Flow Rate Of Water In The Circuit

Electrical Panel

Electrical Panel With Thermal, Miniature And Bimetallic Switches For Electrical Protection Of The Device

IP Above The Electrical Panel

Possibility Of Adding A Controller To The Control Panel

Liquid Line

Liquid Line Includes Solenoid Valve, Sight Glass, Filter Dryer

Using 4-Pipe Accumulator For High Efficiency For Suction And Discharge Line

High & Low Safety Valve To Protect The Compressor At Low And High Pressures

Use Of Receiver To Collect Refrigerant For Repairs

Fan High Pressure Sensor To Control Fan Addition To The Circuit

Elastomer Insulation For All Suction Line Piping To Prevent Heat Exchange

Controller

From Reputable Brands Such As Danfoss Or Kernel, Or Mechanical And PLC

Comments ( 0)